Tailored approaches to biologics development

We understand that every project in biological development has unique requirements. That’s why we prioritize phase-appropriate strategies, ensuring flexibility and scalability to meet your needs from early development through commercialization.

Process development from early development through commercialization

Process development comes in many different forms. We can work to create new process from scratch or help refine your existing process for increased yields or compliance. Either way NorthX Biologics is ready to support.

Upstream Process Development

By developing effective robust fermentation processes we ensure sustainable yields and processes that are scalable and compliant with regulatory expectations. By ensuring reproducible and controlled fermentation and harvest conditions, the amount of impurities progressed to downstream purification steps are minimized providing the basis for a high-quality final product. An effective upstream process ensures yields that supports your clinical trial and commercialization.

We offer:

- Process screening/optimization

- Process verification

- Engineering runs

- Harvest/Clarification development

- Filter screening

- Manufacturing of R&D grade material

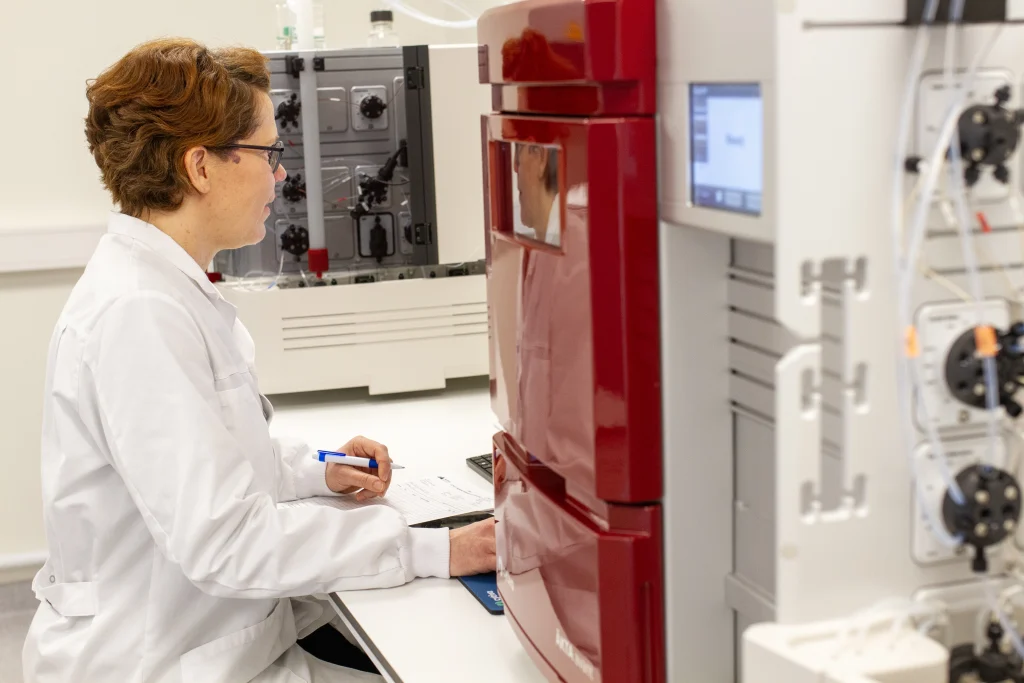

Downstream Process Development

We help you develop scalable effective downstream processes. By using the best available technology, we develop processes with optimized yields and high clearance of impurities. Our downstream capabilities are fully aligned with the upstream processes ensuring a seamless progression. We aim to set a purification process that is simple and robust encompassing the minimum number of unit operations ensuring economically feasible processes.

We offer:

- Resin screening

- Buffer optimization

- Chromatography development

- Ultrafiltration/Diafiltration screening and optimization

- Refolding development

Need a process developed? We are here to help.

Whether it is standalone or in-line with a manufacturing project, NorthX Biologics can support your process needs from start to finish. We ensure phase appropriate development and allow for scalable solutions.